How IoT is making HVAC smart – the top 5 IoT applications for HVAC

Learn how the HVAC industry is harnessing IoT to build new revenue streams, reduce costs, and increase efficiency.

Ready to build your IoT product?

Create your Particle account and get access to:

- Discounted IoT devices

- Device management console

- Developer guides and resources

The Internet of Things is transforming the way contractors manage HVAC systems in both residential and commercial settings. According to Zion Market Research, the global smart HVAC control market will reach $28.3 billion by 2025—evidence that connecting HVAC systems drives efficiency and profitability.

Using the IoT to link HVAC systems helps manufacturers, contractors, and end users monitor their performance and detect issues before they become major outages. IoT sensors send back alerts when they detect a problem, allowing contractors to prioritize service calls, reduce unnecessary truck rolls, prevent equipment failures, meet energy efficiency compliance requirements, and unlock new revenue streams and value-add services.

Let’s take a closer look at some of the benefits and applications of IoT-enabled HVAC solutions.

The top 5 IoT HVAC applications

IoT gives companies opportunities to intelligently monitor and control the performance and condition of HVAC systems. Here are the five primary ways companies use IoT to improve these operations:

1. Preventative maintenance

Traditionally, HVAC contractors respond to problems in the field in two ways. One is after they emerge—when a customer calls to report an outage and request service. This is known as “reactive maintenance.” The company must then deploy technicians to the site to diagnose the problem while the customer endures either excessive heat or cold in the building.

The other is through preventative maintenance on a specific schedule or usage rate. For example, some contractors send out technicians to do yearly tune-ups on a specific day every year. Others may do routine maintenance when a system has reached a certain level of usage.

Either way, traditional maintenance methods often leave managers and techs without a clear picture of the problem. With reactive maintenance, they often go to a job site with only the information the system owner gives them.

With time- or schedule-based maintenance, contractors run the risk of sending someone to do preventative maintenance on a system that is running well or is on the verge of breaking down. The lack of condition-based insight into a system causes major inefficiencies and can be a key driver of high maintenance costs.

Without real-time condition data, service trips often lead to wasted time and money, as HVAC contractors might send out a junior technician to diagnose and fix problems, only to realize they need help from a senior tech to fix it. Likewise, they may send a senior tech to work on a problem that could be solved by a junior one, thus reducing the profitability of the truck roll. The process can become time-consuming and expensive.

With the addition of IoT sensors, HVAC contractors can take a more condition-based approach to preventative maintenance. The sensors gather real-time data from HVAC systems and send it to a cloud-based platform, where contractors can access and assess it. When a problem is detected, such as a drop in efficiency, excessive power consumption, or excess vibration, technicians can look at the readings and often diagnose the problem remotely.

Then they can call the customer—sometimes even before they’ve noticed an issue—and send out the right technician, parts, and tools to service the system in a single visit. The ability to take a preventative approach to maintenance and send the right person for the job on the first truck roll can save time, effort, and costs for contractors—and keep customers happier with uninterrupted service.

2. Energy efficiency

With legacy HVAC systems, energy efficiency can be difficult to monitor and improve. Typically, energy usage data is only discoverable after it’s been consumed, making it difficult to adjust or compensate for. And if there’s an emerging problem with a system, it might struggle along for days or weeks before giving out completely, resulting in more energy waste.

By providing access to real-time data, IoT sensors installed on HVAC equipment can improve energy efficiency by monitoring usage trends and even factoring in weather predictions. The result is better-regulated indoor climate control that keeps power consumption to a minimum. Connectivity also enables HVAC systems to be a key part of IoT-enabled smart grids.

3. Remote system monitoring and control

Legacy HVAC systems simply work until they don’t. Diagnosing problems requires a blend of expertise, tools, time, and effort.

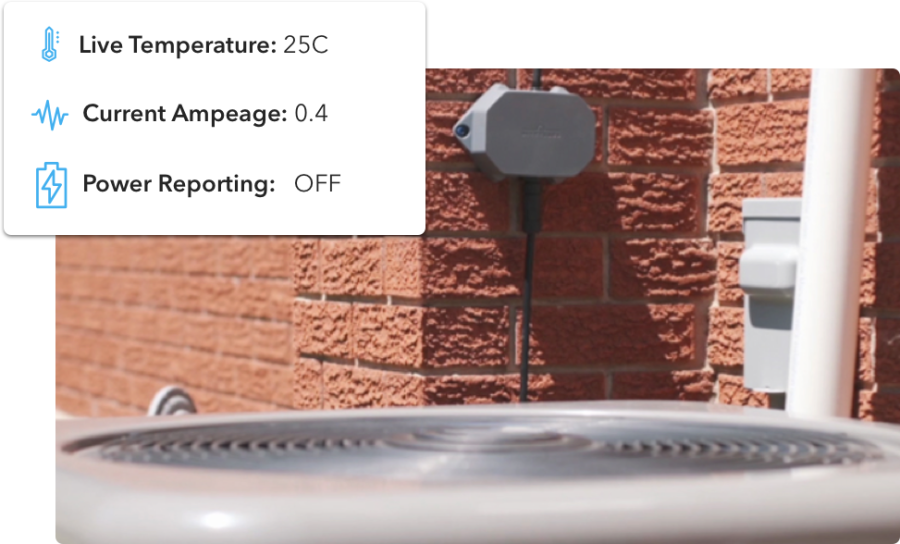

With the addition of IoT technology, remote system monitoring becomes a matter of consulting a smartphone app or website portal, giving homeowners, property managers, and HVAC contractors the insights to diagnose problems from afar.

For example, some sensors provide instant leak detection, while others track key pieces of data such as pressure, vibration, flow, temperature, humidity, on-off cycles, and fault tolerance. Access to this information—at a fine level of detail—allows technicians the insights they need to accurately assess the system’s status. It’s important to understand how the IoT protocols and standards you use can impact the types of data you can collect and how that data will be transmitted to you.

4. Regulatory compliance

Regulatory compliance is a built-in requirement for most HVAC businesses, often requiring a field agent to inspect equipment periodically. And with increasing concerns and requirements around sustainability and air quality, many building and homeowners are looking for ways to demonstrate compliance with government or corporate environmental regulations as well.

Disconnected HVAC systems make it difficult to achieve and document such compliance, often requiring lots of paperwork and manual system checks.

The advent of IoT smart HVAC makes this process much simpler. Real-time system data can be recorded and saved, and some software tools can even automatically generate that data into reports to prove compliance.

5. Recurring service plans

Traditionally, warranties and recurring service plans are a major portion of the average HVAC contractor’s business. A warranty may include built-in service calls or other periodic check-ups, meaning seasonal or on-demand service calls for contractors and technicians.

With IoT-enabled HVAC solutions, contractors can provide the same guaranteed service without needing to travel to the site every spring and fall. Instead, they can proactively monitor and manage the HVAC system and only make service calls when they are truly necessary, providing a true hardware-as-a-service model.

IoT also enables HVAC contractors to provide real-time data to customers via dashboards that show energy consumption and provide energy-saving tips, usage patterns, and even provide remote control capabilities. These products can be bundled with service contracts for additional recurring revenue.

Another new HVAC business model that IoT unlocks is a usage-based pricing model. Similar to how smartphones are sold today—where the cost of the phone is bundled into a monthly contract with little/no money down at the time of purchase—HVAC contractors can install connected air conditioning or heating systems with little upfront investment from the customer and bill them monthly based on usage.

How the leading distributor of HVAC equipment drives value through IoT

With Particle, Watsco has been able to develop products that help system owners and contractors monitor their HVAC systems 24/7.

In the first 16 months after launching its Sentree product, Watsco connected over 2,000 A/C systems, caught 500 issues, and collected 600 million data points. As Watsco continues to innovate, more contractors are signing up to use their connected products.

How to build IoT-enabled HVAC solutions

Building a smart HVAC solution is a complex endeavor with a lot of moving parts. Some enterprises choose to build custom IoT systems from the ground up, requiring expertise in domain-specific engineering, infrastructural development, and resources for scalability, networking connectivity, and security.

Such projects take an average of 18–24 months to complete and require working with many different vendors to provide all the needed elements. The cost of building an IoT product can be up to four times the total cost of ownership—an upfront investment that can be challenging to offset later.

But there’s a simpler option: building with a single integrated IoT Platform-as-a-Service like Particle that provides the edge capabilities (IoT devices and firmware), software, and connectivity needed for deploying an IoT product. We transform our customers into market leaders by giving them the technology and expertise to bring an IoT product to market quickly—six months on average. The cost is much less than taking a DIY approach, averaging one-forth of the total cost of ownership.

Why do industry leaders like Watsco rely on Particle as their HVAC IoT solution of choice?

- It’s an open platform. You can access and share data at the device, system, and fleet level freely with HVAC contractors, engineers, and building managers using our webhooks, APIs, and open-source architecture.

- It’s scalable. Particle can easily grow as your deployment does. We support billions of data samples with more than 25,000 Particle-connected HVAC units in the field. Get the scalability you need to expand your IoT deployment without creating gaps in cellular connectivity, security, or device management.

- It’s effortlessly upgradable. Wirelessly update your HVAC systems with our industry-leading Over-the-Air update capabilities, and never worry about devices bricking again.

- It makes global connectivity simple. Cellular IoT projects can be enormously difficult. Particle’s EtherSIM technology delivers a global network with more than 350 leading cellular carriers and automatically connects to the best available network across available 2G/3G/LTE. Connectivity technologies have you stumped? Check out our guide on cellular vs. WiFi for IoT.

Watsco has built innovative HVAC solutions on the Particle platform over the last few years. The goal? To create the equivalent of a “check engine light” for HVAC systems, allowing manufacturers and contractors to monitor their equipment and diagnose problems remotely.

The resulting product monitors system data from customers’ HVAC systems and sends it to contractors via a cloud-based platform. With the ability to monitor systems remotely and receive alerts when problems are detected, contractors save time and costs by reducing truck rolls and providing more efficient service.

Want to know how Watsco did it? Watch our webinar with Watsco CTO Mario Cruz to learn how he was able to scale an IoT deployment quickly with Particle.