Throughout history, field equipment and sensors have been isolated, relying on outdated legacy systems that are not suited to today’s dynamic and data-centric world. This lack of connectivity has led to a myriad of challenges, including operational inefficiencies, theft, unplanned downtime, suboptimal utilization rates, and a persistent need for on-site visits.

Today, remote monitoring and control is a robust industry with a range of readily available gateways on the market, providing IoT-enabled remote monitoring for equipment and sensors. However, these solutions often come with their own set of complexities, including hardware and firmware design issues, protracted development periods, heightened security risks, and considerable integration and certification expenses. Our conversations with customers have highlighted these complexities and confirmed that many off-the-shelf industrial gateways lack the required customization to meet their specific needs.

Understanding unique industry requirements

At Particle, we work closely with customers who frequently use connected products to monitor sensors, machines, and assets. They aim to remotely oversee their equipment’s status, gather operational and sensor data, and facilitate services such as preventative maintenance to minimize equipment downtime and the need for on-site visits. In fact, “remote monitoring” is one of our most popular use cases at Particle, catering to a variety of applications, each with its own set of requirements:

- HVAC distributors require real-time monitoring of residential air conditioning systems to keep track of their health and performance. This information enables HVAC contractors to proactively service units deployed in the field.

- Oil and gas equipment operators need to periodically visit sites to verify that equipment functions within the manufacturer’s tolerances. They also monitor leaks and emissions from retired assets to ensure safety and avoid non-compliance penalties.

- Generator manufacturers demand smart features that can self-identify mechanical problems, track usage, monitor fuel consumption, and report telematics data. These features simplify generator ownership and operation, making it more cost-effective.

Meet Monitor One: a field-ready, customizable IoT gateway for monitoring industrial equipment

Unlike standard IoT gateways on the market, Monitor One can be perfectly customized to suit the unique requirements of every industrial monitoring use case. Customers can now bypass traditional barriers to entry and gain immediate visibility into their existing machines and assets, no matter where they are deployed, without any of the development headaches and engineering overheads. In particular, the Monitor One features:

- A ruggedized, IP67-rated enclosure for stressful industrial environments

- Built-in support for the most common system interfaces, machine protocols, and sensors including Modbus, CAN, RS-232, and 0-10V for quick integration

- Out-of-the-box mounting support for every possible situation, including walls, poles, and rails

- Off-the-shelf expansion cards to customize I/Os and extend feature sets with minimal redesigns, recertifications, and integrations

- Reference firmware applications for turnkey data capture, control, logging & transmission

- Support for custom connectors with a white-label enclosure

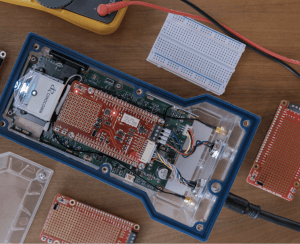

Get started today with the Monitor One Developer Edition

Optimized for rapid evaluation, the Monitor One Developer Edition is designed with simplicity in mind to enable our customers to create a working proof-of-concept in a day. It features everything a user might need for their prototyping needs, including two add-ons, expansion cards for customizing I/Os quickly and easily.

IoT hardware is only as good as the platform it lives on, and the Monitor One Developer Edition inherits the benefits of the Particle integrated IoT PaaS, an “all-in-one” technology stack, spanning edge hardware, edge software, integrated cellular connectivity, cloud-based management software, and developer tools.

You can place orders for the Monitor One Developer Edition here, or talk to our growth consultants who can help you with your scaling needs here.